Biofabricating human tissues enhanced through use of gallium

The manufacturing technique known as 3D printing, now being used everywhere, from aircraft manufacturers to public libraries, has never been more affordable or accessible. Biomedical engineering has particularly benefited from 3D printing as prosthetic devices can be produced and tested more rapidly than ever before. However, 3D printing still faces challenges when printing living tissues, partly due to their complexity and fragility.

Now, with support from the U.S. National Science Foundation, a research team at Boston University (BU) and the Wyss Institute at Harvard University has pioneered the use of gallium, a metal that can be molded at room temperature, to create tissue structures in various shapes and sizes.

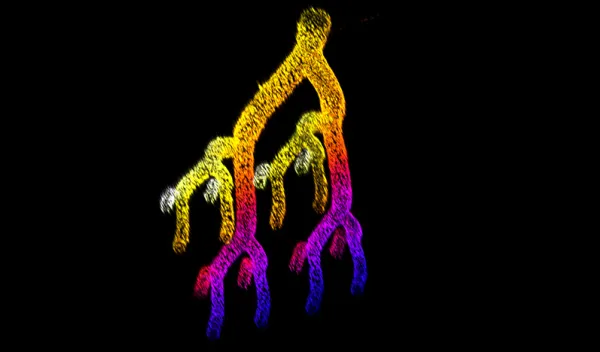

This innovative approach to fabrication, engineered sacrificial capillary pumps for evacuation (ESCAPE), was highlighted in a recent study published in Nature, where the team used gallium casts to mold biomaterials. The scaffolds left behind by these casts are then filled with cells cultured to form tissue structures. Vascular structures were some of the first produced using ESCAPE, particularly because of the challenges faced due to blood vessel complexity. Few techniques exist to build large (millimeter-scale) and small (micrometer-scale) structures in scaffolds made of natural materials, making this multiscale fabrication capability a novel approach.

"ESCAPE can be used on several tissue architectures, but we started with vascular forms because blood vessel networks feature many different length scales," said Christopher Chen, director of BU's Biological Design Center and senior author on the study. Chen is also the deputy director of CELL-MET, an NSF Engineering Research Center at BU funded by a $34 million award from NSF, and co-principal investigator on the award for the NSF Science and Technology Center for Engineering MechanoBiology at the University of Pennsylvania. "Our blood vessel demonstrations include trees with many branches, including dead ends and portions that experience fluid flow. This allows us to model a range of healthy structures as well as diseased abnormalities."

Following the success of reproducing capillary structures, researchers are hopeful these methods can be used to generate distinct tissue structures found in organs. The reliability of these ESCAPE designs will also be tested using computational modeling, further expanding the types of material reproduced using the process.

"CELL-MET allows engineers, student trainees and medical professionals and their patients to collaborate across a broad innovation ecosystem," said Randy Duran, the lead NSF program director for the CELL-MET award. "Using systems engineering, the team has developed a novel method of fabricating structures such as blood vessels that must be produced at scales ranging from microscopic capillaries to much larger blood vessels, all within centimeter-scale heart patches that will have a broad impact on human health."